ubsurface structural failures generate gradual degradation in the pavement structure that works its way up to the surface. GPR pavement forensics surveys can detect unusual subsurface conditions prior to a surface failure. A survey of a multi-lane highway constructed with asphalt over concrete shows growing surface failures directly above joints in the underlying concrete.

Problem

The challenge is to identify zones of incipient failure to plan remedial action. Firefighting emergency repairs are costly and disrupt maintenance budgets. Technology is needed that can define subsurface conditions rapidly and inexpensively at highway speeds without road closure.

GPR Contribution to Solution

Surveys for undocumented and non-visible repair zones were conducted on Highway 401 in Toronto, Canada to plan maintenance and road upgrades. The highway in this area is 40 years old and has seen many upgrades and repairs. Two sites of surface degradation are marked on the Google Earth™ below.

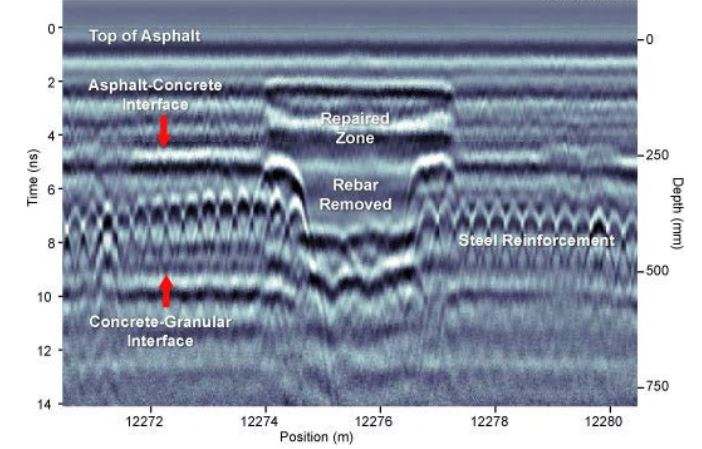

The road construction in the area consists of a 200 to 250 mm layer of asphalt pavement overlying concrete slab which in turn overlies granular material. Multiple passes over several lanes over a distance of about 14 km identified numerous zones of past repairs and structural issues which were neither on record nor visible from the surface.

"Site 1" shows a prior repair zone where part of the entire concrete slab has been removed. The concrete slab to the immediate left is also tilted.

"Site 2" indicates a different construction repair character. There were no clear surface expressions of the repair at the time of the survey.

In both instances, the RoadMap data were acquired at 0.01 m step size. Depths were determined from the localized point scattering diffractions and validated against subsequent core sampling.

Results & benefits

The GPR road and pavement forensics investigation demonstrates the power of GPR for detecting and characterizing subsurface road conditions. Some key benefits are:

- GPR can detect a wide range of changes in road material conditions

- Exploration to depths in excess of 1m are practical

- Operation of ground-coupled systems at highway speeds is practical