The traditional method of subsurface investigation, coring, is destructive and provides information only at single random points. GPR, a proven technology, offers a continuous image of the subsurface providing invaluable information for asset management planning.

Pavement Structures

- Measure pavement structure – obtain continuous subsurface imaging to delineate the top and thickness of asphalt, base, and sub-base layers

- Quickly generate pavement structure reports highlighting pavement layer thicknesses

- Determine construction practices, including concrete under pavement, joints and road cuts that are not visible from the surface.

Pavement Scanning

Cross-sectional view of a portion of the shoulder lane on an interstate highway in California, USA. The colored lines indicate subsurface boundaries with the blue line interpreted as the bottom of asphalt. The road data was collected with a GPS, so it is possible to plot the survey on Google Earth and pinpoint areas of interest.

Asphalt and Granular Thickness

Cross-sectional view of the pavement structure on the CPATT test road at the University of Waterloo, Canada. 1000 MHz GPR imaged the thickness of the asphalt and granular layers. The GPR data was acquired using a SmartChariot configuration, which enables the GPR to be ground-coupled for maximum penetration and data quality. The SmartChariot has an integrated odometer for data collection at equal intervals along the surface.

Runways

GPR is a great tool for imaging the subsurface structure of runways to identify areas of possible voiding and other structural concerns. GPR is also used at airports to locate utilities running across or along runways, taxiways and aprons for mapping and maintenance. The depth slice image here shows soil structure variations under a runway superimposed on Google Earth.

Imaging Substructure

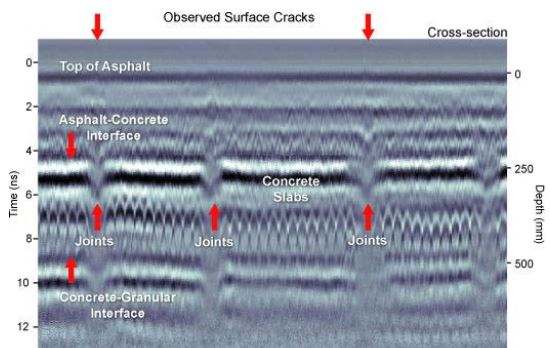

Imaging roads with GPR provides information about where the substructure changes. In this example, after correlating the GPR with other data, the abrupt localized changes were confirmed to be joints in the underlying concrete slab. The change in signal character is associated with fine grained material and water retained in the concrete joints.

Optimizing Core Location

Records of construction and repair may not exist or be hard to locate. GPR systems enable highway engineers to easily assess subsurface conditions over vast lengths of road. Using GPR to determine core locations is an effective way to understand the structure of the road, especially exceptional areas that may not be discovered with random coring.

Pavement Structure Report

GPR is an accurate and cost-effective tool for pavement structure analysis. Combining GPR with the EKKO_Project software enables users to quickly process road survey results into meaningful subsurface information. The inspection of roads has just become a lot easier and more affordable!

Pavement Forensics

- Map subsurface features to determine cause of surface failures

- Identify structural deterioration and identify where to focus repair efforts

- Gather full structural information to prioritize infrastructure spending

- Monitor structures to ensure public safety

Detecting Cause of Road Surface Problems

Subsurface structural failures generate gradual degradation in the pavement structure that works its way up to the surface. GPR pavement forensics surveys can detect the extent of the problem, find a possible cause and identify other areas that may have the problem prior to a surface failure.

Detecting Road Cuts

One of the major causes of road degradation occurs when contractors cut into the road to install or repair utilities. GPR can image historical road cuts, even where the surface asphalt had been replaced so the cut was no longer visible on the surface.

Mapping Road Cuts

The city of Toronto, Canada was interested in calculating how much contractor road cuts were costing the city for additional road repairs and maintenance; information required to charge a reasonable fee for future road cuts. In this example, 3500-line-kilometers of GPR data was collected to determine the number and location of road cuts on major roads. The GPR depth slice data, plotted on Google Earth, shows how road cuts appear as high amplitude linear features cutting across the road.

Dowel Bar Verification

A GPR survey at a bus terminal revealed where the contractor had missed adding dowel bars between the concrete slabs; critical for weight transfer and structural support. This allowed the asset-owners to determine where to focus repair efforts, minimizing the costs of the project.

Buried Targets

- Locate buried targets such as utilities, under the road, and other embedments.

Locating Utilities under Roads

GPR can be towed behind vehicles to quickly locate metallic and non-metallic utilities buried under roads for infrastructure maintenance and planning projects.

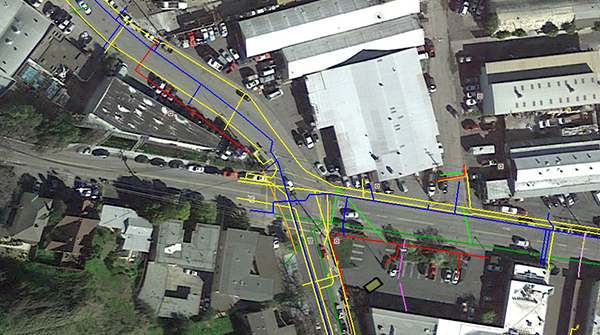

Plotting Buried Utilities on Google Earth

Interpreted utilities can be plotted on Google Earth.

Output GPR data to 3D Plotting Software

In this example, a zig-zagging GPR survey line is plotted in CloudCompare, a free, 3D plotting software to show the orientations and positions of targets.

Sinkholes & Voids

- Detect and map hidden hazards like sinkholes, road cuts and voids before they become a safety concern.

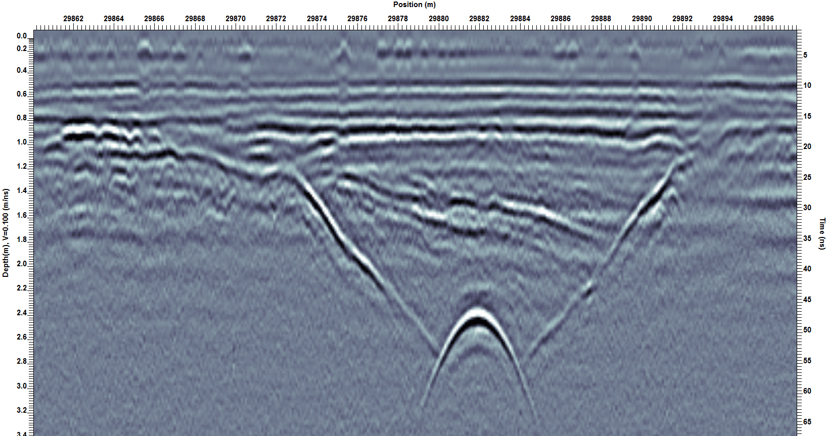

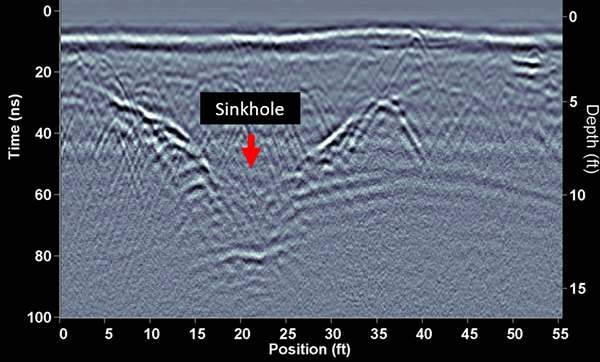

Sinkhole Detection

GPR can detect the void from a forming sinkhole before it reaches the surface and causes damage.

Preventative Maintenance

After an empty, taxiing airplane fell through the concrete at an airport in the USA, causing $1.5 million USD in damage, airport authorities were concerned that there could be other voids on the airport grounds. A GPR survey of the area revealed another void that seemed to be associated with a large pipe running through the area.

Mapping Voids

Performing GPR grid surveys and examining depth slices is a common way to locate voids. In this example, the red anomaly indicates a potential void and provided an indication of where corrective action was needed.

Bridge Deck Deterioration

- Determine anomalous areas and guide core locations

- Easily create signal attenuation and deterioration index maps according to the ASTM D-6087 standard

Bridge Deck Evaluation

Monitoring the state of bridge decks is an ongoing need to evaluate deterioration. Corrosion of reinforcing steel and delamination of asphalt and concrete can be sensed with GPR.

Bridge Condition Assessment

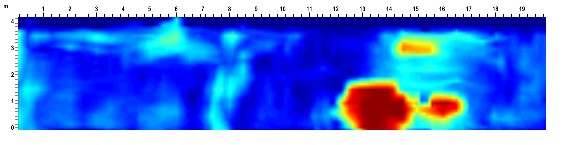

The degree of corrosion of metal reinforcing is a major concern for bridge decks and similar concrete structures. Since the presence of saline water and corrosion by-products causes strong attenuation of GPR signals, measuring and mapping the variations in GPR signal attenuation has become an accepted practice to assess the condition of concrete structures.

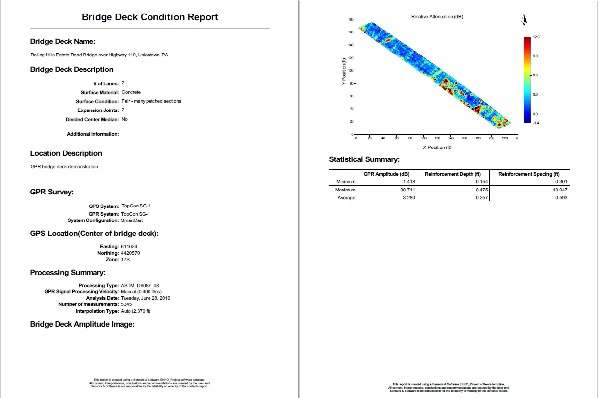

Bridge Deck Condition Report

The Bridge Deck Condition Report module outputs a PDF report that includes a GPR response amplitude map and the statistical summary of all the picked rebar in a bridge deck. Map images are generated as either a Raw Amplitude map or a Deterioration Index map that uses the processing outlined in ASTM 6087 (Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar).

Bridge Deck Deterioration

- Determine anomalous areas and guide core locations

- Easily create signal attenuation and deterioration index maps according to the ASTM D-6087 standard

Bridge Deck Evaluation

Monitoring the state of bridge decks is an ongoing need to evaluate deterioration. Corrosion of reinforcing steel and delamination of asphalt and concrete can be sensed with GPR.

Bridge Condition Assessment

The degree of corrosion of metal reinforcing is a major concern for bridge decks and similar concrete structures. Since the presence of saline water and corrosion by-products causes strong attenuation of GPR signals, measuring and mapping the variations in GPR signal attenuation has become an accepted practice to assess the condition of concrete structures.

Bridge Deck Condition Report

The Bridge Deck Condition Report module outputs a PDF report that includes a GPR response amplitude map and the statistical summary of all the picked rebar in a bridge deck. Map images are generated as either a Raw Amplitude map or a Deterioration Index map that uses the processing outlined in ASTM 6087 (Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar).

Bridge Construction Practices

- Visualize and measure subsurface rebar structure, including spacing and cover

- Determine dowel bar placement and orientation

Bridge Mapping

Bridge engineers are often interested in knowing how a bridge was constructed including the number, spacing and depth of metal reinforcements such as rebar, dowel bars and tie bars. GPR provides a fast, non-destructive method of imaging and mapping these embedments for bridge maintenance and rehabilitation.

Bridge Forensics

- Identify inconsistencies and potential quality issues in bridge construction

Bridge Construction Quality Control

GPR can be used to measure the depth to reinforcement. The cross-section shows an area of a bridge deck where the depth of rebar cover quickly increases more than 2.5 inches over about 5 feet – useful information for quality control on bridge deck construction.