Unlock a world of subsurface information with one quick scan.

Conquest® 100 allows you to get rapid, reliable results and reduce the need for destructive testing. It is a light, portable device that provides a fast, non-invasive method to gain accurate insights of objects below the concrete surface, even on a curved surface or column.

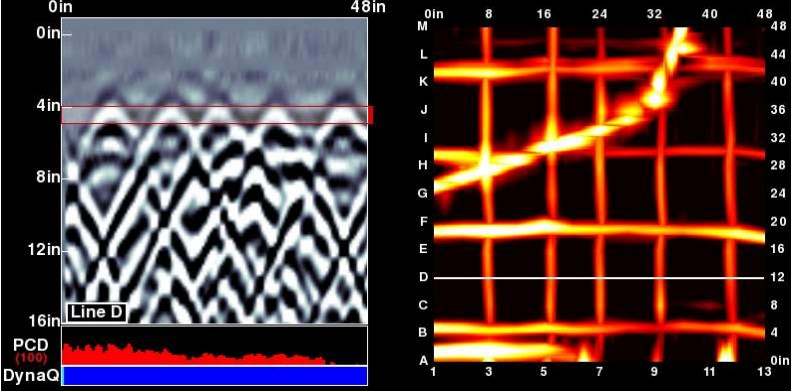

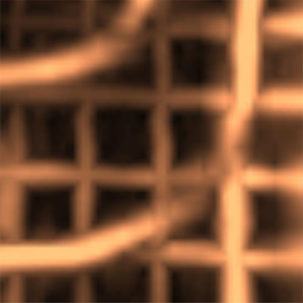

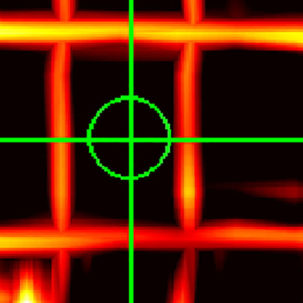

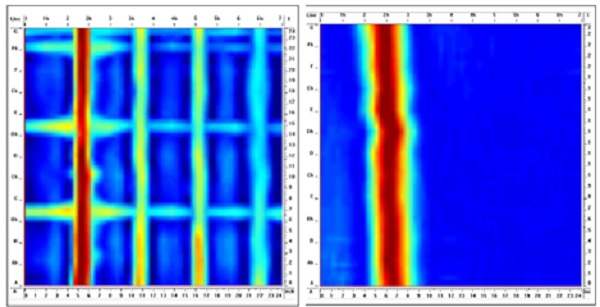

Conquest® 100 GPR increases safety by detecting rebar, post-tension cables, metallic and non-metallic conduits as well as current-carrying wires embedded in concrete. Once your concrete scan is complete, the system allows you to e-mail information directly from the field in the form of a Wi-Fi mini-report. With the Conquest® 100 Enhanced, you also have the option to add the powerful optional EKKO_Project™ Software to view your data and make client-ready reports in minutes once back in the office.

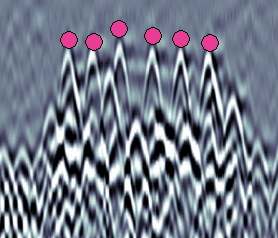

- High-Resolution Touchscreen: See targets clearly with intuitive on-screen operation

- Easy Reporting: Transfer information wirelessly to your smartphone using Wi-Fi

- Optional EKKO_Project™ PC Software: Our all-inclusive software solution for managing, displaying, processing and interpreting GPR data.

- Swappable Li-Ion Battery: Never lose time with long-lasting swappable batteries.

- All-in-one transportation case.

- Collect data in a comfortable standing position using the optional resizable handle for the Sensor Head and carry harness for the Display Unit.

- Bluetooth remote triggering for easy one-handed operation when using the Conquest® 100 collapsible handle.