elsonville, Ohio is a small Appalachian community in southeastern Ohio on the Hocking River. The region is known for its beautiful wooded hills and hollows and its thick buried clay layers deposited at the end of the last ice age. In the late 1800s it was one of the region’s most famous brick manufacturing centers, and the Nelsonville Brick Company cranked out millions of bricks per year using dozens of large, circular kilns.

In 1937, the Nelsonville Brick Company folded and the site was eventually abandoned. Today, a few of the circular brick kilns and square chimneys are still standing in a road-side park, but most of the kilns have been knocked down and their exact locations are no longer evident on the surface.

Nelsonville is also home to Hocking College, a two-year college that formerly had an archaeology technician training program—it was one of the few in the U.S. On two occasions I have taught a short course on the use of geophysics in archaeology to students at Hocking. During one of these short courses, the class visited the roadside park at the Nelsonville Brick Company and the students conducted a GPR survey in three areas in proximity to the surviving kilns. Prior to the survey the location of additional kilns was not known. The students placed GPR survey grids in the most open and easily accessible areas.

On a brisk, late winter day with a dusting of snow on the ground, the students collected three GPR grids using a Sensors & Software Noggin® 500. Grid 1 is the largest, 37 x 20 meters, while Grids 2 and 3 are approximately 20 x 20 meters each. All grids were collected with lines in the Y direction, spaced 0.5 meters apart. GPR samples, called traces, were collected every 2.5 centimeters along each survey line (41 per meter) so, with a total line distance of about 3000 meters for the 3 grids, more than 110,000 individual traces were collected in the area.

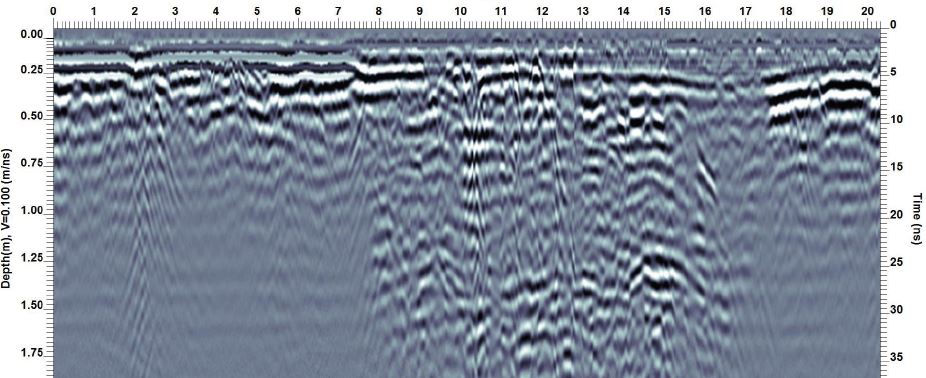

The survey didn’t take long and the students had little trouble running the GPR unit (except for missing a couple of lines in Grid 3—students are students!). During the survey it was clear from the images we saw on the Digital Video Logger (DVL) that the penetration depth was more than 2 meters and there were some very reflective features and layers below the surface at the Nelsonville Brick Company site (Figure 1).

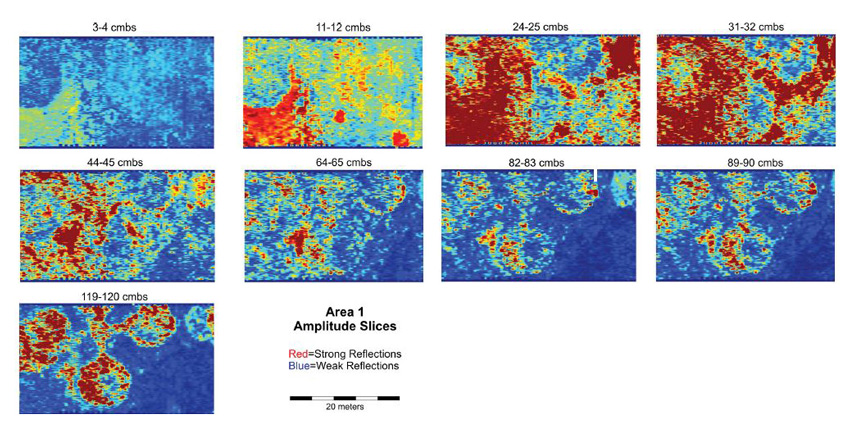

After the survey and back in the classroom, the class used the SliceView module of the EKKO_Project™ software to quickly process the data and create a series of amplitude slices at various depths. Much to everyone’s surprise, the GPR data was loaded with the foundations of flattened kilns!

Looking at the depth slices from the three grids, it was clear that we had located a number of different circular kiln clusters. In Grid 1 (Figure 2), one chimney appears to be connected to multiple kilns by an underground tunnel.

In Grid 2, the class located portions of three kilns and in Grid 3, which had recently been graded down to improve the roadside drainage but the group were still able to detect large circular features at depth (Figure 3).

By collecting the GPS position at one corner of each grid, the global positions of the grids were added in post-processing; this allowed the depth slices from all three grids to be displayed in their correct positions on Google Earth™ (Figure 3).

Looking at a sequence of slices makes it more apparent that there are different kinds of features present at different depths (Figure 4). For example, the kiln foundations do not become apparent until about 50-80 cmbs (cm below surface). Some of the shallower featuresinclude what are probably driveways and walkways made from brick (see the 31-32 cmbs slice in Grid 1 (Figure 4), for example. Needless to say the Nelsonville Brick Company site is an ideal setting for demonstrating to students the utility of geophysical survey instruments in identifying subsurface structural remains. Without accurate maps tied to known points on the surface it is impossible to know what is present beneath the surface at this site without conducting destructive and expensive excavations. My experience is that former industrial sites are some of the best places to use GPR because there are so many hard targets to detect.

Further, because GPR produces 3D datasets that can be examined at different depths, it allows the class, to some degree, to tease apart the often complex sequences of construction and demolition before even one spade of earth is turned over.

Click here to learn more about Noggin® Ground Penetrating Radar.