AUSMOS is a utility locating robot developed by ULC Technologies using a Sensors & Software NOGGIN® 250 GPR system and the SPIDAR® SDK (Software Development Kit). Hear the story of the rapid development of this innovative device.

Sensors & Software Inc., located in Mississauga, Canada, and part of SPX Technologies, Inc. (SPX) has designed and manufactured ground penetrating radar (GPR) products for over 30 years. Our GPR brands include NOGGIN®, pulseEKKO®, Conquest®, Rescue Radar®, LMX®, and SPIDAR®. In 2022, we introduced the SPIDAR® SDK (Software Development Kit), which allows customers to control any NOGGIN® or pulseEKKO GPR system from their own application. This provides the ability to add Sensors & Software’s proven, world-class GPR technology to existing products, build a platform that combines GPR and other sensors, or create a unique GPR system for niche applications that are not being served by current GPR hardware. The SPIDAR® SDK was featured in our January 2022 newsletter.

Interestingly, one of the SPIDAR® SDK’s customers is a sister company under the SPX umbrella. ULC Technologies, LLC, based out of Hauppauge, New York, specializes in robotics development and RaaS (Robots as a Service) for the energy, utility, and other industries to solve a wide range of operational challenges. ULC was approached by the UK gas distribution network, SGN, and Transport for London (TfL) to assist with excavation operations, by developing a semi-autonomous robotic system for the detection, location, and mark-out of below-ground infrastructure in urban areas. This robot is known as AUSMOS™ (Automated Utility Service Mark-Out System, Figure 1)

The two most proven technologies used for utility-locating around the world are electromagnetic induction (EM) and ground penetrating radar (GPR). For the GPR system, ULC collaborated with Sensors & Software by utilizing our NOGGIN® 250 GPR system, SPIDAR® hardware, and SPIDAR® SDK software (Figure 2).

ULC’s comments on the development process:

As part of the AUSMOS project, we integrated a variety of Sensors & Software products into our platform which included their newly released SPIDAR® SDK. The SPIDAR® SDK manages system control and GPR data acquisition through HTTP access which makes the integration to be OS and language ignorant. These considerations make the product compatible with a broad spectrum of third-party platforms. To support this integration, Sensors & Software provides documentation, SDK functions and example code which enables more user-friendly integration. By understanding the flow of the system operation, a custom package can be built effectively from the SPIDAR® SDK. – Baiyang Ren, PhD

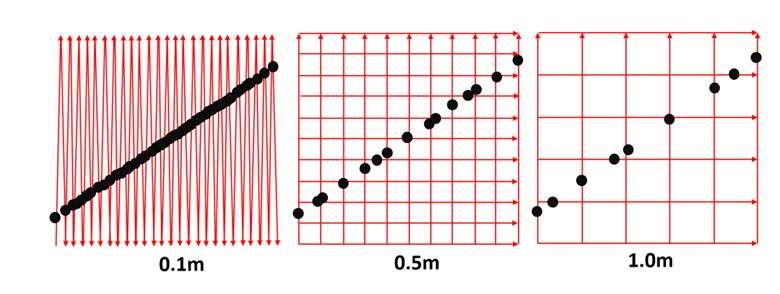

AUSMOS collects high-density GPR and EM data as it scans the region of interest, creating a grid-like pattern with very tight line spacing, typically 10 cm (Figure 3, left). AUSMOS achieves centimeter-level localization accuracy through the implementation of advanced mathematical algorithms, constantly calculating the robot’s current position. This also enables the system to maintain its localization accuracy in highly congested areas or inside buildings where GPS is typically denied.

Human operators are trained to collect grid data with 0.5 (Figure 3, middle) or 0.25-meter line spacing, but it is common to see corners cut by collecting data at a 1.0-meter line spacing (Figure 3, right) or more. In comparison, AUSMOS typically collects data with a 0.1-meter line spacing. This results in a highly dense GPR data set, 2.5 to 10 times more than a typical human operator can easily collect. The likelihood of identifying an object as a potential target of interest, in this case, a utility, increases with the number of times the GPR crosses it. While the utility can be identified with a coarser line spacing by “connecting the dots”, the confidence it is a real target increases with the number of crossings (Figure 3), especially in locations with multiple utilities.

Furthermore, with AUSMOS, data collection is executed with higher spatial accuracy than a person can achieve, removing human bias or possible error due to fatigue. The robotic deployment ensures data is captured with greater consistency from site to site and user to user, resulting in a more accurate map.

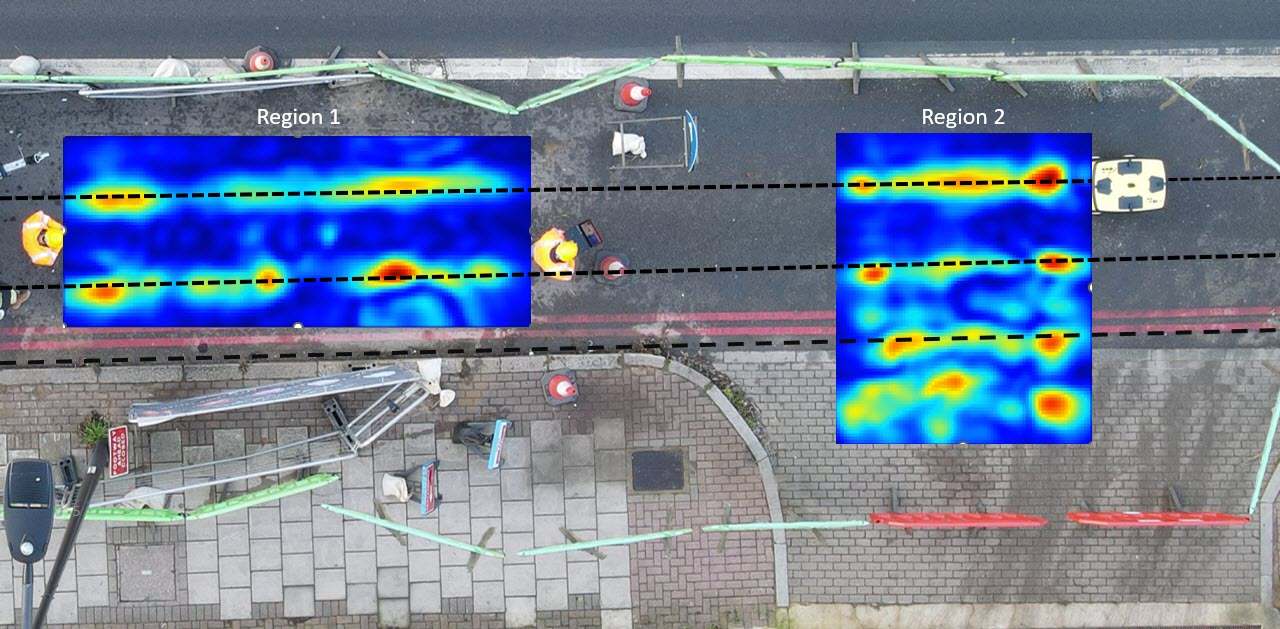

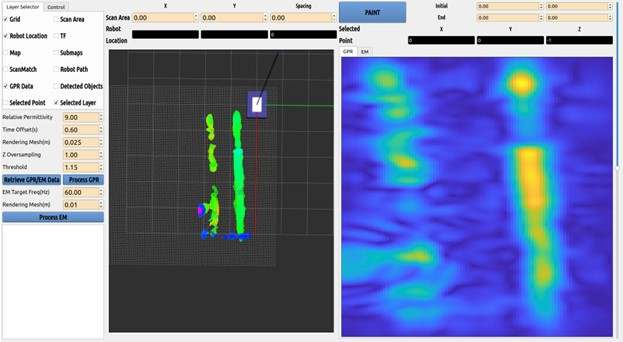

The data is then processed immediately on-site, delivering high-resolution depth slices (Figures 4 and 5) and easily interpretable 3D point cloud images (Figure 5) of utilities and other reflective objects in the subsurface. This enables AUSMOS and its operator to mark-out utilities on site.

These example data sets from the UK trials show multiple utilities detected in 2 rectangular grids, showing correspondence to each other, as well as exposed pits on-site, highlighting the localization and consistency of the robot.

AUSMOS is an example of the type of highly specialized engineered location and measurement products that SPX Technologies is known for.

For more information about AUSMOS, see https://ulctechnologies.com/technologies/ausmos-gpr-mapping-robot/

For more information about SPIDAR SDK, see https://www.sensoft.ca/products/spidar-sdk/overview/